Types of Conveyors

- aegisenggWith the rise in various equipments and machines, the production in the industries has also increased. Moreover, today the machines and tools are highly advanced that helps in raising the manufacturing of products easily. Initially there were limited products and the production was also narrow. Nowadays there are so many products and so many conveyor manufacturer india that make the work extremely easy and uncomplicated.

Conveyors are an excellent tool that assists in the production process, in many industries. A conveyor plays the role of trolleys and trucks and reduces the manual working of the employees. Conveyors help in moving goods from one place to another in an industry. When the goods are to be conveyed in a stationery path or straight lane, conveyors are used. The machine has helped many different sectors by providing the transportation facility for goods.

There are various types of highly advanced and technical conveyors discovered today that helps various sectors of the industry. One can find the conveyors such as belt conveyor, screw conveyor, pan conveyor, redler conveyor, chain conveyor and many others. Let’s have a look on all types of conveyors in detail.

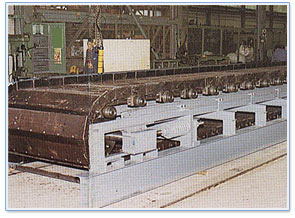

Belt conveyor: The belt conveyors are used in the industry where goods are to be moved in a straight path. The product gets stick to the belt and moves along with the belt. The belt conveyor has the speed set according to the requirement of the product. The width and length of belt can be chosen according to the goods to be moved. Light and medium weight goods can be easily transferred from one place to another.

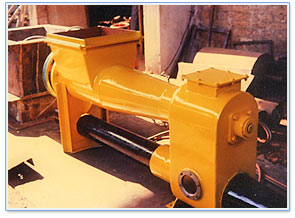

Screw conveyor: The loose materials can be moved from one place to another with the help of screw conveyors. The materials such as grain, coal and others can be carried with screw conveyor. Screw conveyors are one of the most extensively used conveyors in the processing industry.

Chain conveyor: Chain conveyor consists of one or more chains so that the goods can be directly loaded on it. The chain conveyor comes in a wide variety of attachments with chain conveyor it. There are parallel chains that can move pallets in the different departments of the manufacturing unit.

Roller conveyor: roller conveyor can be an electric one or power free. The materials to be transferred should have a hard surface. The roller conveyor helps in moving cartons and boxes from one end to the other end. Many roller conveyors are an alternative to wheel conveyors.

Pneumatic conveyor: The material that are light weighed and requires air pressure to move can be conveyed through the pneumatic conveyors. The pneumatic conveyors can include three types of systems: pressure system, vacuum system and pressure as well as vacuum system.

Telescopic conveyor: Bulk material handling is not everyone’s cup of tea. It is not possible for everyone to manage huge telescopic conveyor machines and stocks. There are several equipments that help in material handling in big units as well as projects.

The machines such as conveyors, bucket elevator, Crusher, stacker and others are used in bulk material handling process. Conveyors are the most used equipments in the material handling process. Conveyor makes the transporting work be extremely easy in large units. The above mentioned conveyors are just a glimpse of its types.